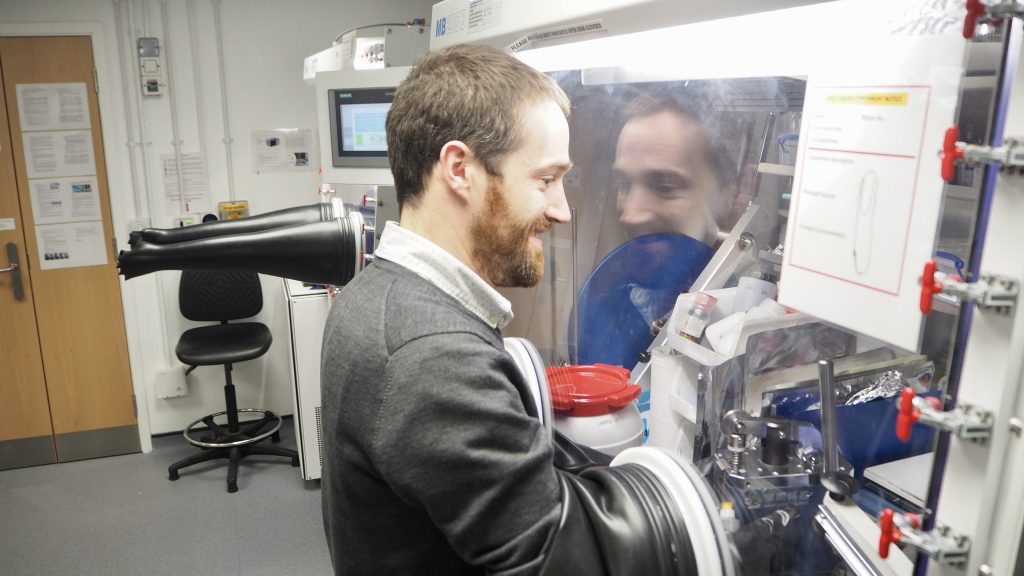

We spoke to Professor Rob Weatherup, Fellow in Materials Science, about his work in sustainable technologies.

You specialise in ‘interface science’; can you tell us what that means?

Interface science is about understanding the boundaries between a material and its operating environment, which is often where both beneficial and undesired reactions take place. In Li-ion batteries, for example, charge is stored by transferring Lithium ions across the interface between a liquid electrolyte and a solid electrode. At the same time, the electrolyte can breakdown producing undesired products and wasting charge. In interface science we try to observe the chemical changes happening and how the structure of the interfaces change depending on how fast we charge or which voltage we charge to. Understanding what’s going on typically requires piecing together information from several characterisation techniques and then developing a model of the processes occurring. Although that can be challenging, when it all comes together you can get a much deeper insight into what limits battery performance, helping us to make significant improvement on the current technology. This approach isn’t just limited to batteries, but we can explore a whole range of phenomenon that happen at surfaces, from materials growth to corrosion.

Why this area? What inspired you to pursue a career in Materials Science?

I went to university thinking I wanted to be an electrical engineer and got quite a long way down that path. I really enjoyed my final year project, designing a device that allowed you to turn the lights on/off at home over the internet, and so decided to do a PhD. I chose a project focussed on graphene which was the exciting new material at the time, and I thought within a few months I’d be making new graphene transistors and devices. The real challenge turned out to be making the graphene reliably, and I got hooked on trying to understand and control the growth of two-dimensional crystals, such as graphene, on metal surfaces using a technique called chemical vapour deposition. Since then I have explored a whole range of areas in my research from catalysis, to device electronics, to electrochemical energy storage. What’s really inspired me along the way is the opportunity to always be learning and adopting new ideas. In both my teaching and research I try to make sure I’m always slightly out of my comfort zone so I’m getting a new perspective and that certainly helps to keep things interesting.

What challenges do you face in your work to make better batteries?

One of the key challenges we’re facing at the moment is trying to increase the amount of energy stored for a given mass, whilst also reducing battery cost. A promising way to do this is by swapping some of the cobalt in current battery electrodes for nickel, which is cheaper and gives a higher voltage battery. Unfortunately, this comes at the cost of increased reactions between the electrode and electrolyte meaning the batteries degrade more quickly and can’t be recharged as many times. We’re trying to understand the nature of these reactions so that we can try and supress them using methods such as coating the electrode surfaces or including additives in the electrolyte.

More and more people are driving fully electric vehicles; just how far have things come and what’s the next stage in innovation?

It’s quite amazing how rapidly the cost of Lithium-ion batteries has fallen. In the last decade alone the price for a battery with storage capacity has fallen by around seven-fold, meaning that a passenger car that can travel >200 miles on a single charge is now much more affordable. Electric cars are still quite expensive compared to their petrol equivalents, but the good news is that battery prices are expected to keep falling over the next 5-10 years which will hopefully make them a more realistic prospect for all of us. One of the big remaining challenges is whether it’s practical to extend electrification to much heavier vehicles, such as buses and lorries, which consume energy at a much higher rate than a car. One option might be to charge them more regularly, and there are schemes trying to do this wirelessly whenever a bus stops to pick up passengers, but this requires improvements in how fast Li-ion batteries can be charged. Another approach is to use much larger battery packs, but these get expensive and bulky when we’re thinking of powering an HGV. Therefore, some researchers are looking at alternative fuels such as hydrogen, or methanol for these applications as a means of transitioning away from fossil fuels.

Does your work explore other ways in which technologies can be more sustainable?

If it happens at an interface, my group probably has at least some interest in understanding how it happens, and developing new experimental methods to do this. One of the main directions we’re exploring at the moment is how to produce alternative fuels sustainably. This includes looking at catalysts that combine waste carbon dioxide with hydrogen to make methanol, both as a fuel and a precursor for the chemical industry. We also look at ways to electrochemically split water into hydrogen and oxygen, which has huge promise for storing the intermittent energy produced by renewable sources for when it is needed. The problem at the moment is that current approaches to do this efficiently rely on expensive metal catalysts such as platinum and iridium. We’re currently trying to develop new catalyst nanoparticles made from earth-abundant materials that can help drive down the cost of this technology.

In 2020, you received a £1.5 m grant from the European Research Council. Can you tell us a bit about the project this funding supports?

This project is called “Extending Interface Science To Atmospheric-pressure Reactions”, and is aiming to develop new experimental techniques to observe the interfaces of working catalysts and battery electrodes in their operating environment. Many of the most powerful interface-sensitive techniques we currently have require vacuum conditions, and so we can only look at these materials after they’ve failed by taking them out of the reactor or battery pack, which might cause them to change. This project is looking at how we can use extremely thin membranes (1-2 atoms thick) as barriers between these vacuum conditions and the higher pressure gas or liquid environments relevant to catalysis and batteries. The project has been running for 18 months and we have some nice results showing that our new methods seem to be working pretty well. This is always a relief when you’re doing high-risk science, as there are a lot of dead ends along the way and you have to get used to regular failure and trying to adapt your approach to overcome that.

What will be the impact of this research project?

The most immediate impact is for the researchers in academia and industry, who will gain access to a new set of experimental tools to help study the systems they are working on. We already have quite a lot of interest from other research groups and battery/chemical companies and we’re discussing with them how these approaches can be applied to answer their questions and help them better understand the materials they are working with. In the longer-term we are trying to use these techniques to improve our understanding of what makes a better electrode or catalyst for a specific application. Getting to the bottom of the reactions occurring on the surfaces of these materials and why they happen, will be extremely useful in the development of new sustainable technologies.

Where’s your favourite place in Oxford?

Probably Oxford’s Museum of Natural History. I have two young sons and we have spent many (often rainy) weekend afternoons indulging their love of dinosaurs and other unusual animals. It’s housed in this incredible Victorian building which is in itself very impressive, but nevertheless very accessible, and we always manage to find something we didn’t spot on our last visit. There’s also a strong materials science slant to how minerals with different structures form in the earth’s crust, so I have to be careful to hold myself back from turning our visits into tutorials on phase transformations.

Photo: Lijin An